Note: A reference letter from my supervisor is available upon request.

Who is Corvus Energy

Corvus Energy is the world’s leading supplier of batteries for the maritime industry; powering electric and hybrid marine vessels.

My Role

As part of the prototyping team at Corvus Energy, my role was to design, build, and test prototype parts for their new battery systems. My job responsibilities included: designing parts and assemblies in SolidWorks; manufacturing parts, often with a Tormach CNC mill or 3D printer; performing tests on various prototype parts and systems; writing thorough documentation for my designs and tests.

Skills

SolidWorks

A significant amount of my time was spent designing parts in SolidWorks. I improved upon my skills, particularly when working with large assemblies, and parameter-based models.

Machining and CNC

One of my favorite parts of this co-op was how much time I got to spend hands-on, making parts. I got very familiar with the tools in the machine shop, especially the CNC mill. The experience I gained here greatly complemented my previous machine shop training.

I also wrote a few pieces of machining documentation for future co-ops. I created a machining guide, with a focus on the Tormach conversational machining. Additionally, I wrote instructions on how to square a vice on the CNC mill using a dial indicator.

In addition to machining, I worked extensively with 3D printers. I used both BambuLab FDM printers and resin printers.

Documentation and Presentation Skills

I greatly improved upon my documentation skills through this co-op. For every single task I did, I wrote documentation of some form. For tests, I would write a plan, a test journal, and a test report. For large projects, I would write documentation going through the design and manufacturing process. For small tasks, I would still write about them in my bi-weekly sprint recaps. At the end of each sprint, I would present the work I did to my team and some of the engineering management.

My Projects

Unfortunately, I’m unable to talk about most of the work I did, due to IP issues. I’ve included a few of my projects below, but do not have anything about most of the work I did on our prototype batteries.

Battery Lifting Jig

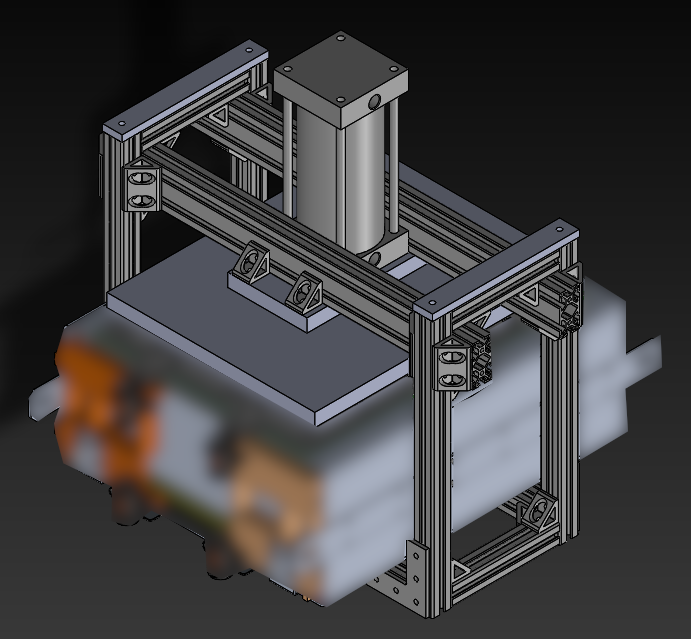

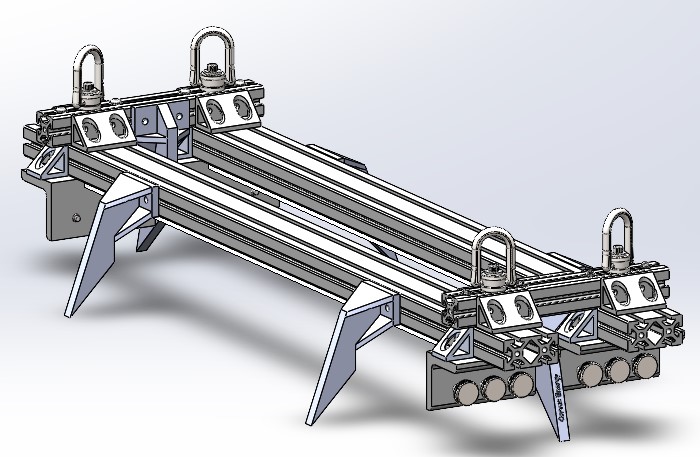

I designed and built this battery lifting jig in preparation for our team to work on a particularly heavy project, requiring the use of a hoist to move the prototype around. I designed the assembly in SolidWorks, making use of off-the-shelf parts from McMaster-Carr and aluminum extrusions.

I machined a few custom parts on the CNC mill, and 3D printed some of the non-structural parts. To validate my design, I ran some FEAs in the local area where the prototype mounted to the jig; the location that I determined to be the weakest point. In the final weeks of my co-op, I made modifications to this jig, such that it could be adapted for the team’s next two projects.

Battery Testing: Short-Circuit, Thermal Runaway, Vibration, Environmental Sealing

I performed and assisted with a variety of tests during my co-op. The most notable of which was a battery short-circuit test. For this test, I analyzed the risk of shorting battery cells at different states of charge, and therefore at different voltages. For this test, I first wrote a test plan, and designed a remote actuation system to start the test. I then wrote a safe work procedure, and assembled a test battery module. I instrumented the module with thermocouples and voltage pickups, and took measurements such as resistances between different areas of the battery module. Lastly, I ran the test, keeping a test journal, and documented my results in a test report.

I also assisted with thermal runaway testing and vibration testing. This involved building the systems being tested, managing documentation and data acquisition, instrumentation, and visiting third-party labs. I wrote a test plan to characterize the performance of different thermal insulators, however my co-op term ended before that was performed.

Adhesive Testing

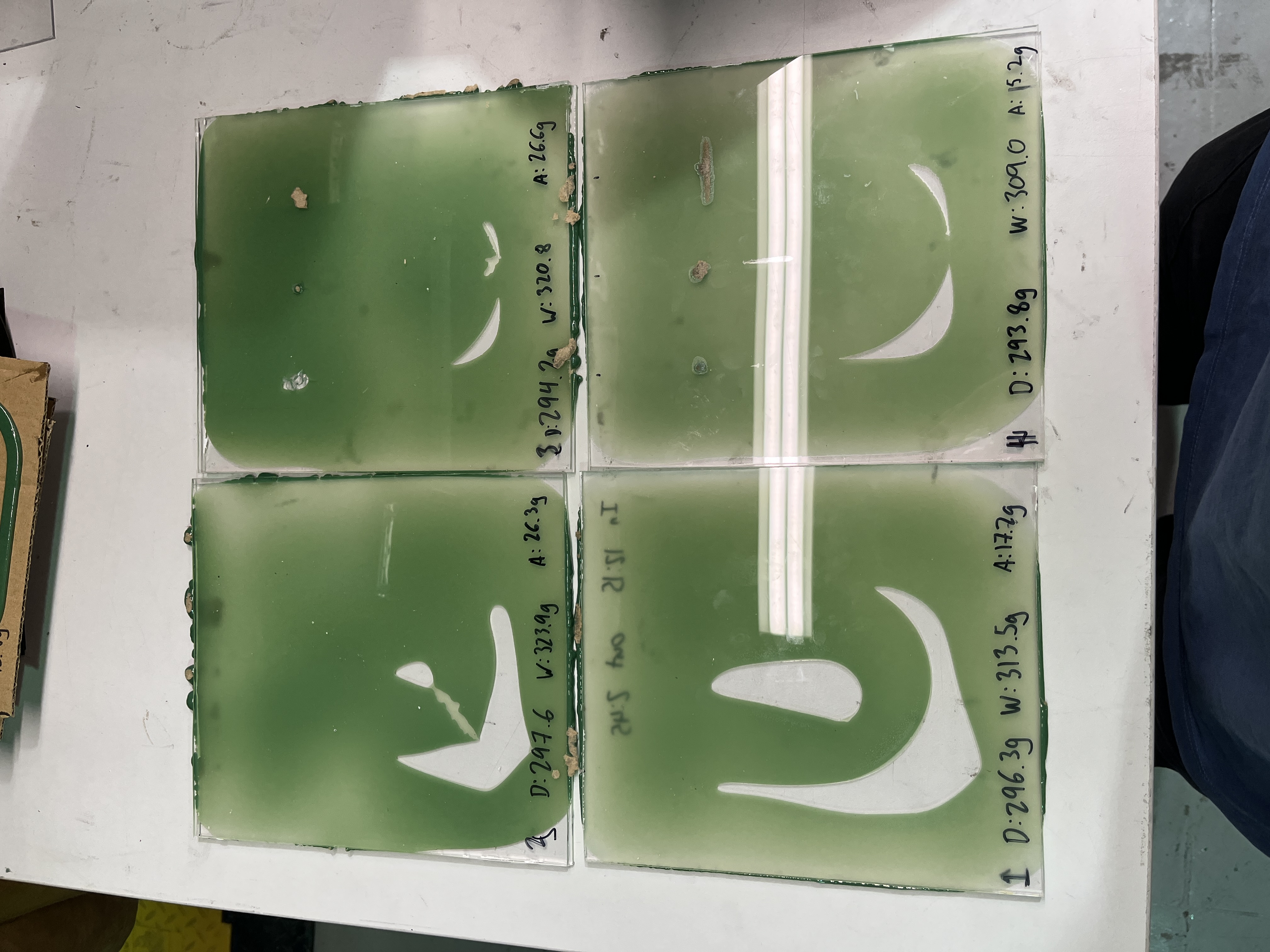

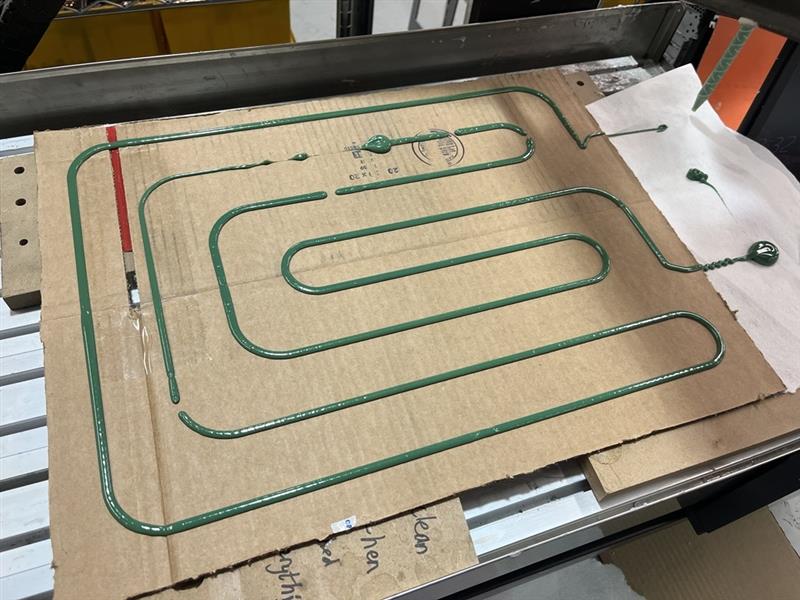

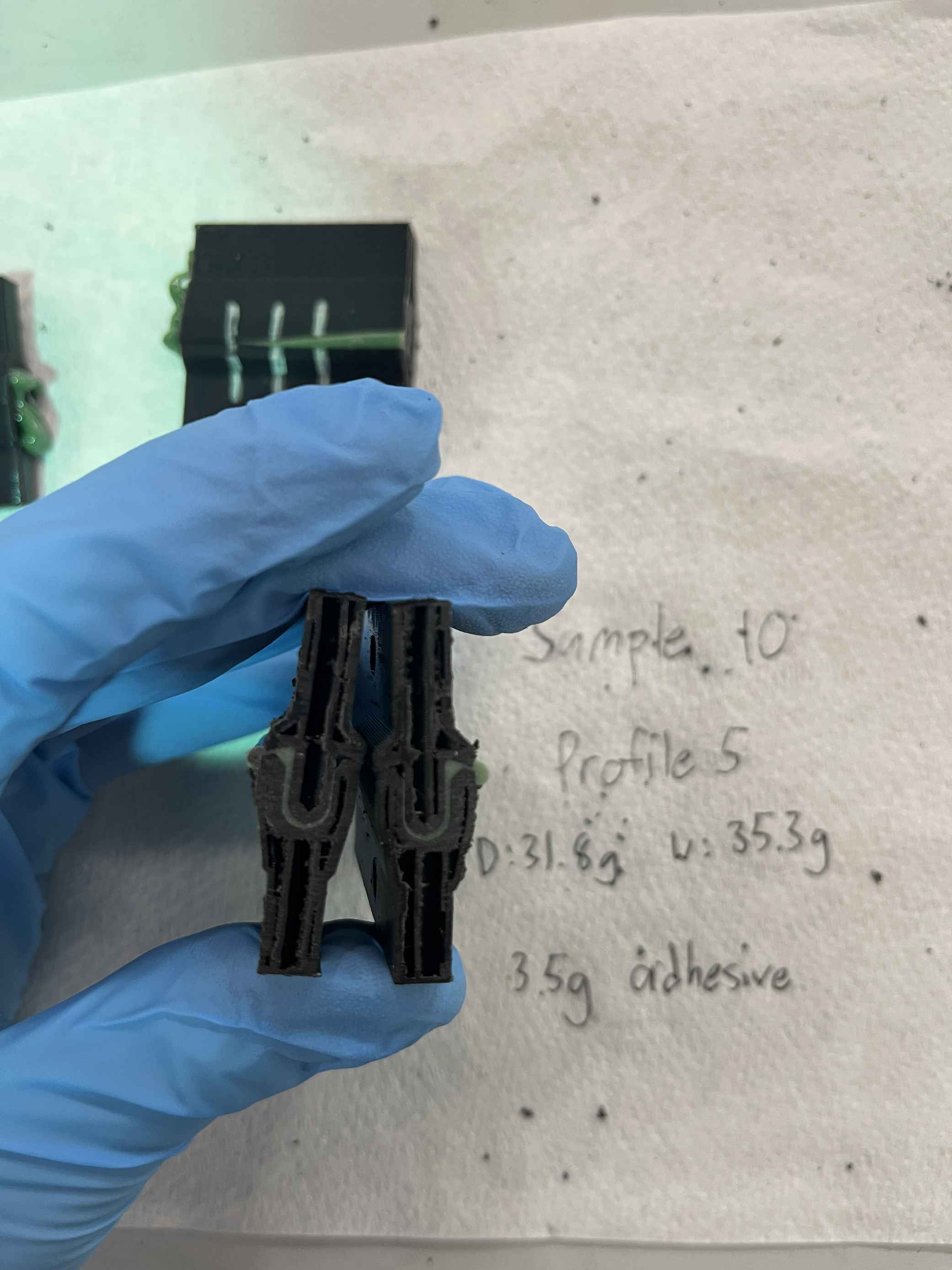

Throughout the course of my co-op, I performed several tests involving adhesives. Below are images from a few tests involving adhesive wetout patterns.

Left: A small scale test analyzing wetout of different amounts and patterns of adhesive. Centre: The left test was scaled up to full size. I can’t show photos of the prototype, however, this is the result of the GCode I wrote for the CNC adhesive dispenser as part of the full scale test. Right: I performed several tests to characterize the adhesive wetout of different joint geometries.

I also assisted in shear tests of adhesive samples, and characterization of adhesive performance under different temperature and humidity conditions (not pictured).

Pneumatic Press

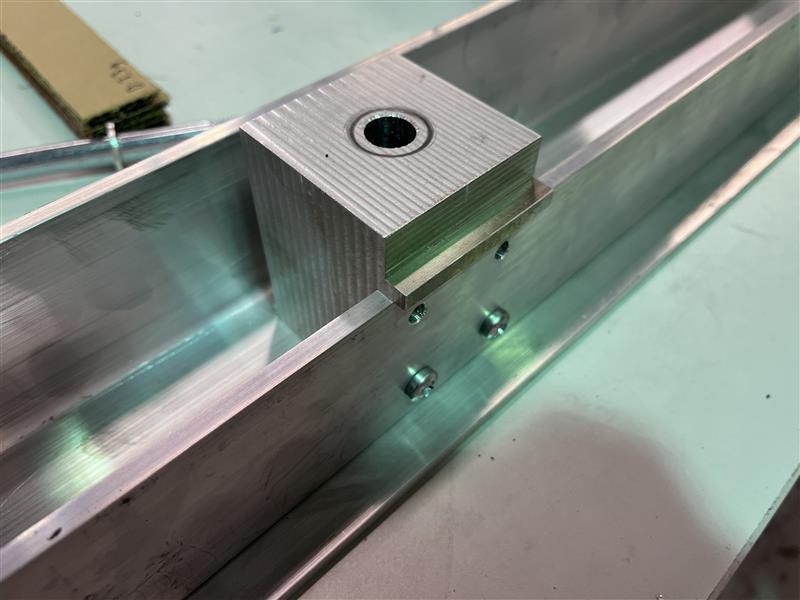

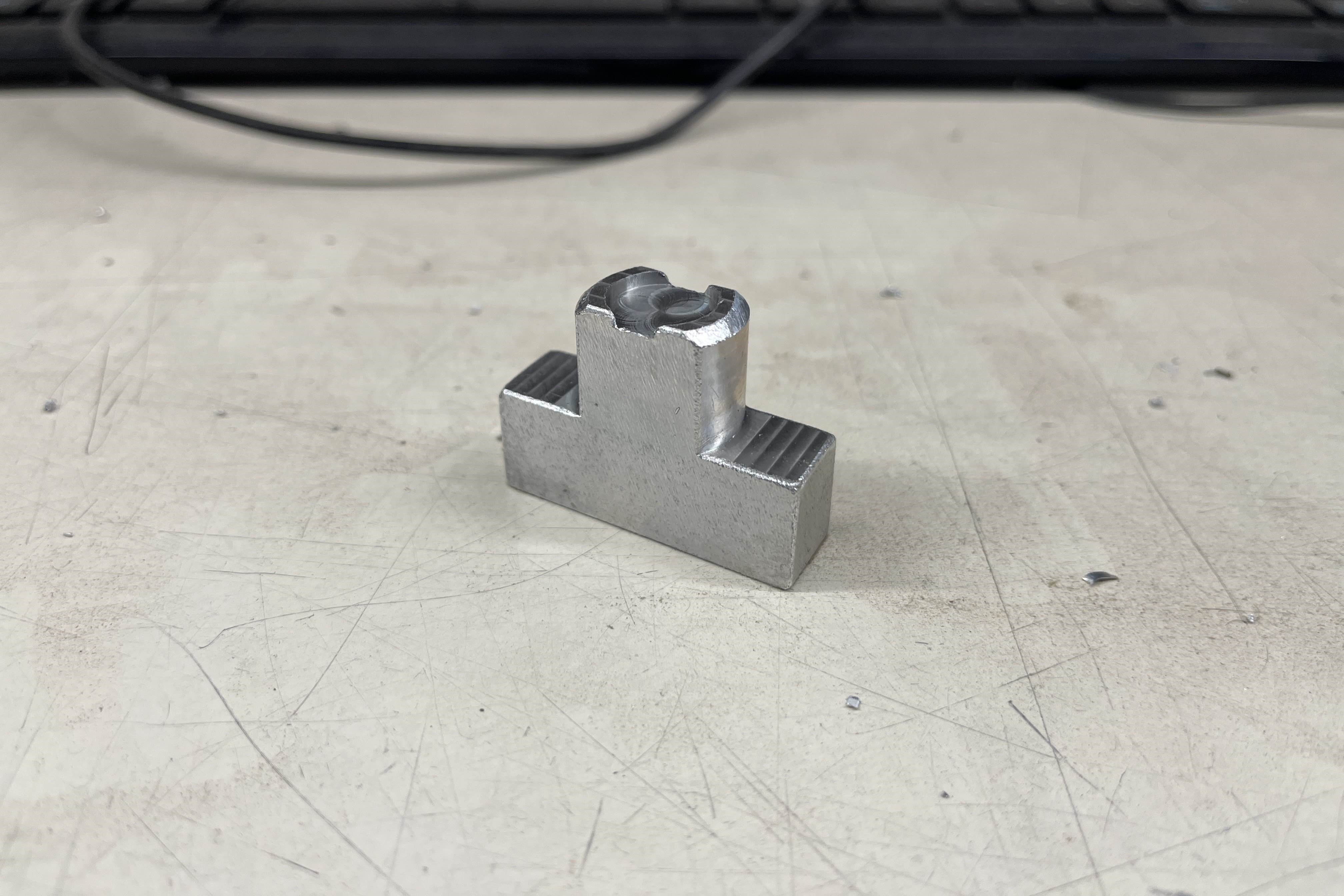

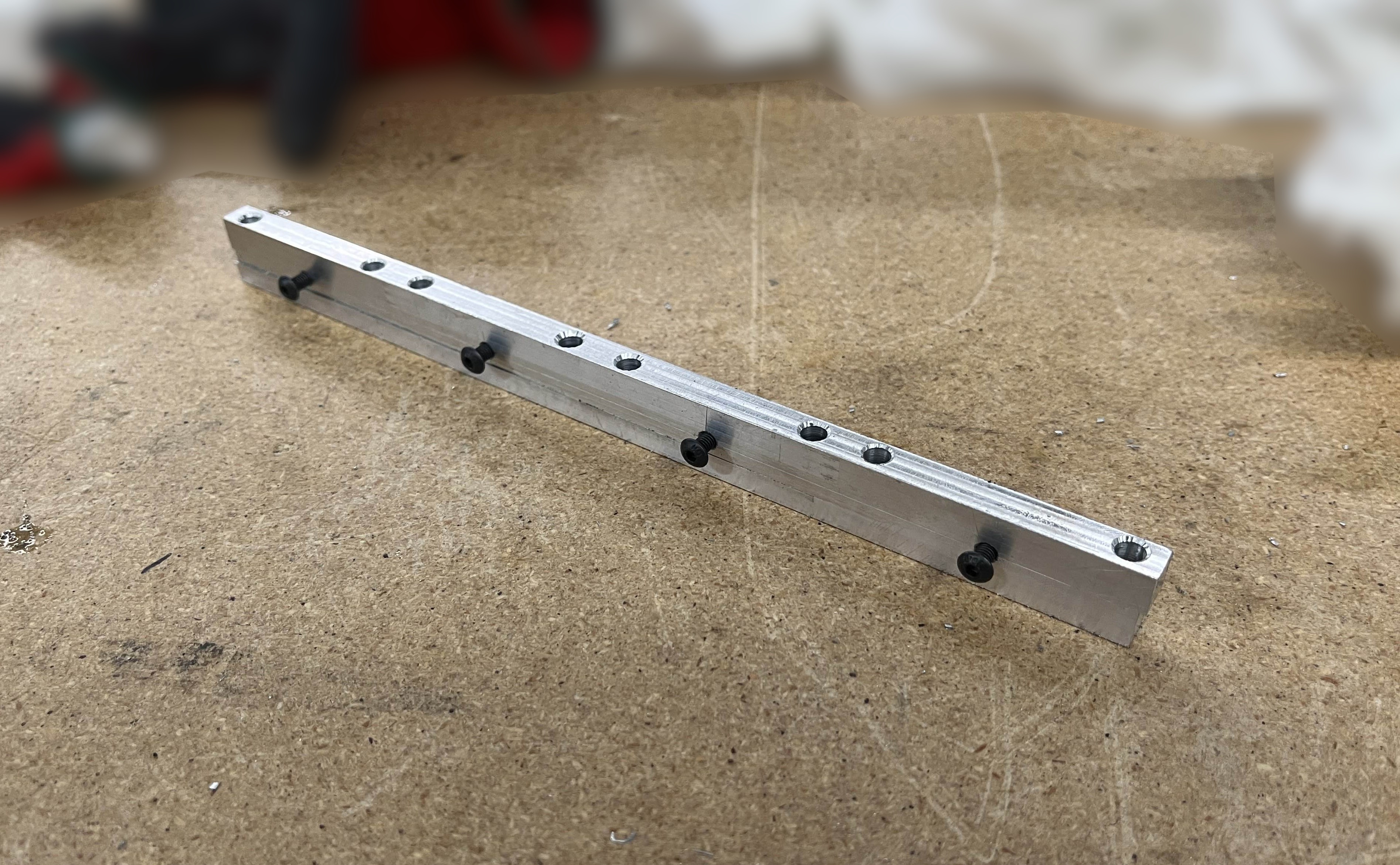

This is a pneumatic press I designed to be used in the assembly of battery prototypes.